High pressure diesel cycle combustion

The common heavy duty high performance engine runs according to the diesel cycle. Over time the efficiency of these, especially the really large ones, have reached efficiencies as high as 50 % and above. The conventional fuel is oil, usually either refined marine diesel or marine gas oil with lower viscosity or some type of heavy fuel oil with higher viscosity and a higher degree of impurities solved in the oil. Generally, a larger engine at lower speed is able to burn heavier fuels.

For operation on methanol, several methods is possible.

+ DME

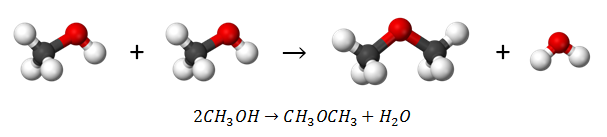

Dimethyl ether (DME) in contrast to methanol is an excellent diesel fuel with high cetane number (>60) and reasonably high energy density (28,430 kJ/kg). DME is in essence dehydrated methanol; two methanol molecules are combined to produce one molecule of DME and one molecule of water. DME is gaseous in ambient conditions and require a pressure of about 5 bar to stay liquid but do not require cryogenic storage.

Figure 3: The chemical reaction where two molecules of methanol become one molecule of DME and one molecule of water.

DME has in particular been identified as a potential energy carrier for trucks. Recently there has been some attention to a project from Volvo to use bio-DME from the pulp industry to fuel trucks in Sweden. The system employed by Volvo use DME in liquid form all the way from the fuel station to injection in to the cylinder.

The combustion process is similar to ordinary fuel oil; DME is injected to the cylinder at TDC and is ignited by the high pressure and temperature. Compared to an ordinary production engine the required modifications should to a large extent be limited to the fuel supply and injectors.

A hurdle for DME is the fact that it is gaseous at ambient temperature and pressure conditions. This requires pressurised storage tanks and also makes bunkering and demands on pipes and bunkering stations stricter as higher pressures is demanded. Also, as DME is not available as a worldwide commodity and no distribution network exist an introduction of it as a global fuel is difficult and expensive.

+ OBATE

A closely related alternative to DME is called OBATE™ (On Board Alcohol To Ether). It is a system developed by Haldor Topsoe that converts methanol to DME on board of a ship. That way no distribution network for DME is needed as well as simplifications for bunkering and on board storage as methanol is liquid at ambient pressure and temperature. In the OBATE system methanol is converted to a mixture of DME, water and methanol that is used as fuel in the engines.

Pressure pipes are still required between the OBATE-system and as well as required modifications to the fuel system. As the fuel have better self ignition properties compared to raw methanol extensive modifications to the engines might be avoided.

A pilot installation of an OBATE system has been tried in the SPIRETH project. Two Scania DI13 auxiliary engines and an OBATE reactor have been installed on board Stena Scanrail, a Ro-Ro vessel in traffic between Gothenburg and Frederikshavn.

Preliminary results from the projects indicates that, in contrast to DME, OBATE is unlikely to function as well in a diesel cycle without further modifications to the engine. The water and methanol content in the fuel lowers the cetane number and modifications such as higher compression ratio and/or ignition enhancer might be needed for an engine to work well at all running conditions on OBATE.

The system also requires room for the reactor. Based on the installation on board Stena Scanrail the required space would likely be somewhat larger than the separator room required for heavy fuel operation [1]. Further development of the OBATE reactor will significantly reduce the size.